ACI Eco Concrete Competition Questions

**NOTE: The objectives listed on our web page have been updated to correspond with the rules. Please refer to the RULES for the most accurate and up to date information.

Q: I am a little confused about the mass allocation in the EcoConcrete calculation tool. From the Summary sheet, it seems that the environmental impact of GBFS/kg is lower than PC's for all categories. In other studies though, the mass allocation approach seems to lead to the opposite, with much larger adverse environmental impact coming from GBFS in several impact categories. Do you know if it is because of the particular iron production process considered or because it is a combined mass and economic allocation?

A: The environmental impacts of slag is relatively smaller than PC. Please refer to the references provided in the database worksheet.

Q: The competition rules states that content of coarse aggregate (above 5 mm) should by more than 30%. Could We estimate the border point of coarse aggregate (5 mm) based on European size sieve analysis? We can use the standard grading chart and calculate the amount of aggregate above 5 mm in very simply way.

A: The volume of aggregates with sizes larger than 5 mm shall be more than 30% of the total volume of aggregates. This should be reflected in the mix design table (where the mass of constituents for one cubic meter of mixtures stated). Reviewers can be able to recognize the volume of coarse aggregates based on the specific gravity of the constituents as well as the corresponding graphs of the sieve analysis.

Q: Can we assume that our BCS and ACS should have the same mass?

A: The BCS and ACS mix designs usually have different unit weights. As for one cubic meter mixture, the masses would be different. Further discussion of the design of concrete mixtures, incorporating various alternative materials, with team advisor or mentor is recommended.

Q: Are we supposed to use the quantities that are already in place on the Calculation Tool spreadsheet as our Base-case Scenario or are we suppose to develop our own unique Base-case Scenario?

A: The BCS mix design and curing condition shall comply with the rules specified in Section 2.3-2.5. The default values of the mixture constituents can be adjusted according to these rules.

Q: Should the total volume of our mixture be taken into consideration with regards to reduction?

A: The replacement of various alternative materials, which have different unit weights than primary materials, can eventually alter the unit weight of ACS compared to BCS. Teams shall mention the mass of constituents for one cubic meter of concrete mixture in the spreadsheet, the report, and the poster. In fact, one cubic meter of ACS shall be compared to one cubic meter of BCS.

Q: Can we use the Vancuver style for textual citations?

A: Following citation styles can be used in the report and poster. One citation style shall be consistently followed for all the references. (MLA, APA, Chicago, Harvard, Vancouver)

Q: From System Boundaries under LCA section, do we need to make a similar figure (1) for each material?

A: One system boundary for each case is enough to include all the cradle-to-gate processes. The dash line box in Figure 1 delimits the system boundary explained in Section 2.5. Therefore, all the processes located inside the box are included in the system boundary of this system analysis (For more information, you may refer to ISO 14044). https://www.iso.org/standard/38498.html

Q: Should the graduate student who’s assisting us be added as a “team member?”

A: Each team can ask the help of one graduate student (Ph.D. or master student) to participate in the mix design and the simplified life-cycle assessment (LCA), and the student shall be mentioned in the report. It means that jury members can recognize the name of the graduate student in the report. They should not be added as a member of the team.

Q: We would kindly like to know the composition of cement classified as normal type I. Are all the materials corresponding to this cement clinker + gypsum? Also, Cement Type II - Moderate Resistance to Sulphate and Type V - High resistance to Sulfate are present in the ASTM nomenclature. In the NBR (Brazil) standard, we only have the type of cement with resistance to sulphate. What is the difference between the types of cement with sulfate resistance of the American standard? So that we can evaluate the choice of our material.

A: The C150 standard addresses the chemical and physical properties of these portland cements. Teams are encouraged to read those specifications to understand if their portland cement are complied with the limitations of the standard. In fact, if there is a portland cement in Brazil with the similar specifications of type II, this team would be free to use it for the eco concrete competition. It should be kept in mind that blended cements are prohibited to use in the BCS.

Q: Is it possible to get a Calculation Tool file in the US system of units (lbs, ft, etc.) for the Eco Concrete student competition?

A: It was decided we would standardize the use of SI units, as accommodating dual units has imposed quite a challenge (especially for prices per ton, and for cost relative to concrete volume). In addition, the US metric is not defined for the environmental impact assessment, such as ecotoxicity and carcinogenic. To keep it constant, we went for the SI metrics.

Q: I could not find the location option for Bangladesh in the Life 365 software. Would you please guide us on how to proceed in this regard?

A: Please refer to section 2.5 of the rules for the default selections in the Life 365 tool.

Q: We are confused about the source and travel distance of SCM. In Bangladesh, we produce fly ash from the power plants and limited GGBS from the steel industry, however, no production of silica fume. Some companies import silica fume from Scandinavian sources. In that case, if they wish to use silica fume, should they consider the distance from a Scandinavian source or local importer location?

A: Yes. If a material is imported from another country, the distance and mode of transportation from the exporting country to the local importer AND from the local importer to the university shall be considered and calculated.

Q: For some ratios (fly ash, slag, and silica), the service-life value becomes more than 100 years. Then, should we have to restrict the design service-life in between 100 years? Or, can this "service-life" value be more than 100 years as shown in the Life-365 software?

A: Teams shall set the analysis period to 100 years. The value of more than 100 years should be considered for the service-life result in this case.

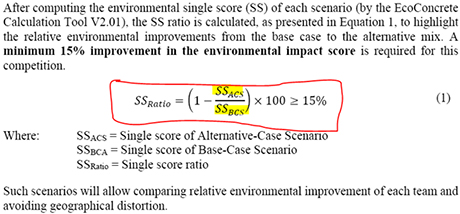

Q: There is something wrong with the equation (p.7, ecoconcrete rules_final.pdf) given in the screenshot. If the motivation of this competition is properly followed the value becomes negative with the present situation. Please confirm.

A: To clarify the equation, here is an example:

Suppose the global warming score of BCS is 400 kg CO2eq and your effort shows a reduction to 300 kg CO2eq for ACS. Your score for this reduction is [1-(300/400)]*100% = 25%

Q: The aggregate mix used to produce the alternative case scenario (ACS) concrete mix may contain by-product aggregates, co-products? or just recycled coarse and fine aggregates?

A: As mentioned in section 2.4.1 of the rules, virgin aggregates for both mixtures are only allowed.

Q: Is it permissible to use powdered inorganic compounds as an additive for the alternative case scenario (ACS) concrete mix or should it be used as a replacement for fine aggregate?

A: To effectively assess the durability of ACS mixture, only powdered materials specified in the Life 365 software are allowed.

Q: For the fulfillment of our aggregates supply chain, our university can transform a recycled but not industrial or large-scale aggregate, can we consider our university as a processing plant? or it must be a founded and industrialized company for the transformation of aggregates.

A: As discussed in the rules, only virgin aggregates are allowed for this version of the competition. If the virgin aggregates are processed at the university, the transportation distance from the quarry to the university shall be accounted for the LCA calculation.

Q: For the ECO CONCRETE competition, we are wondering which SCM’s are allowed outside of Fly Ash, Slag Cement and Silica Fume. For example, if non hydraulic lime was used to satisfy part of a 40% total replacement cement material, and additionally, if that replacement with lime had a positive impact on the carbon footprint of our mix design, would this material be allowed by ACI? Or, are allowable replacement materials limited to a strict set of SCM’s?

A: The answer to the question is only those SCMs specified in the Life 365 software shall be incorporated.

Q: Could you please specify, for this competition, only the binder material can be replaced by supplementary cementing material (SCM), and the aggregates in both the BCS and the ACS must be the same? Can't they be replaced by recycled aggregates? In the frequently asked questions, they mention that up to a 100% replacement of the aggregates with recycled materials can be made. That does not cover for this version of the competition?

A: Only virgin aggregates are allowed, both for BCS and ACS mixtures.

Q: The competition rules state: “To achieve this goal, teams are encouraged to seek out and use local sources of environmentally friendly materials, such as supplemental cementitious materials (SCM)." Does it mean that we cannot use recycled materials to replace aggregates in the alternative case scenario (ACS)? That being the motivation of the competition for the design of an ecological concrete.

A: Only virgin aggregates are allowed, both for BCS and ACS mixtures.

Q: Is the use of chemical admixture allowed?

A: Yes.

Q: Is it allowed to replace drinking water with wastewater, since we have the possibility of using it?

A: Tap water can be replaced only with recycled water. In this case, the amount of energy required for the recycling processes shall be manually added to the tool with appropriate citation.

Q: How do you define a virgin aggregate?

A: Aggregates whose raw material sources are not supplied from any waste or previously manufactured materials.

Q: Can you please tell us a bit of detail about how the presentation slides should be made and what should be its content? Also, should the presentation slide be contained identical visuals as similar as the video or it can be a separate entity from the video?

A: The content of presentation and associated scores are provided in Section 2.7 of the competition rules document. There is only one presentation that will be recorded and the same slide deck will be submitted. The previous concrete solution videos can be appropriate examples. Examples

Q: We have noticed that it was not written in the rules that we have to actually produce/create concrete. What we have understood is that only simulation is needed. However, the transportation of raw materials was mentioned. In light of this, I would like to seek clarification regarding the following concerns:

1. Do we need to produce the concrete mix?

A: Aggregates whose raw material sources are not supplied from any waste or previously manufactured materials.

2. Do we have to also show the transportation of raw materials for our BCS?

A: Yes, the transportation modes and distances from the plants/factories to the university (hypothetical ready-mix plant) shall be incorporated in the LCA calculation.

Q: What materials are we limited to in replacing or adding to the concrete mixture?

A: The portland cement in the BCS mixture shall be partially replaced by slag, fly ash and/or silica fume.

Q: For example, are we allowed to use e-plastic waste or recycled brick instead of gravel?

A: Aggregate replacement is not allowed.

Q: Can we use copper slag or steel slag and replace sand?

A: Aggregate replacement is not allowed.

Q: Or are we just limited to fly ash and furnace slag to replace cement only?

A: The portland cement in the BCS mixture shall be partially replaced by slag, fly ash and/or silica fume.