FRP Competition Questions

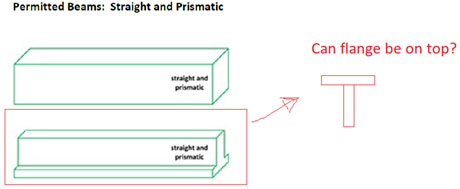

Q: ACI FRP competition testing, should a T-beam specimen be tested in its conventional orientation or inverted?

A: This is a design decision for the team. The specimen will be loaded on the surface designated by the "X" markings on the competition day. These markings must be applied by the team prior to competition day.

Q: Which test does the competition actually require: standard slump cone, slump flow, or either?

Standard slump cone.

Q: Do cylinders need smooth tops, or is capping/grinding allowed for compression tests?

A: Capping and grinding are permitted for compression tests by the team prior to the day of competition (by the date the mix and cost form is due). The cylinder brought to the competition the day of testing is for weight purposes only.

Q: I also have a question about the minimum beam width that we can use: the width of the beam must be greater than the plate that will be used to apply the load (50 mm)?

A: There is no minimum beam width. However, students are cautioned that there is no lateral bracing supplied to the beam during testing.

Q: I have a question about the rods, how can we tie the rods to each other? Which materials can we use for that?

A: 2.6.3. Reinforcing supports are not permitted in the 850 mm clear span. Any manner of bar support including chairs, wires [ties], and precast concrete blocks may be used outside the clear span, as long as the bar support does not act to enhance the behavior of the structure, such as by anchoring the bar in the concrete; these bar supports are NOT included in the total cost. All reinforcement supports must be made from nonmetallic materials or must be galvanized (zinc-coated) or coated with nonmetallic materials. In the past, student teams have used plastic zip ties.

Q: Is there any specific requirements or limitations on the concrete cover in the FRP beam for the competition?

A: No, there are no minimum cover requirements in this competition. Student teams should consider the purpose of cover in their design.

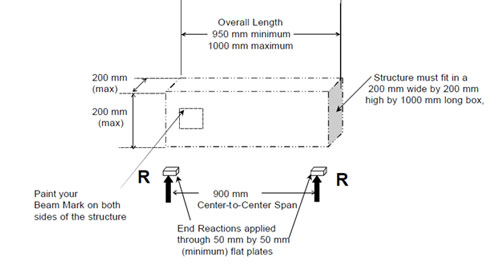

Q: The support location is fixed, in the report the figure showing the beam it is mentioned that the center to center of the beam is 950 mm and clear span is 850 mm. So in this case we cannot have a beam of length 950 mm (the minimum allowable). Could you please clarify what is the center-to-center support location?

A: This is a design decision for the team. The specimen will be loaded on the surface designated by the "X" markings on the competition day. These markings must be applied by the team prior to competition day.

Please see the figure below for clarification.

Q: ACI FRP competition testing, should a T-beam specimen be tested in its conventional orientation or inverted?

A: This is a design decision for the team. The specimen will be loaded on the surface designated by the "X" markings on the competition day. These markings must be applied by the team prior to competition day.

Q: Can there be any diagonal outline elements in the cross-section? Or only vertical and horizontal ones?

A: Because all sections must be prismatic, (of constant cross-section along the entire length) diagonal, as well as vertical, impressions on the surface of the structure are not permitted.

Q: How to anchor rods at the ends of a beam?

A: This decision is at the discretion of the team. Section 2.5.7 states “Mechanical anchorages, if used, must be made from the FRP reinforcing materials supplied for the competition.” Section 2.6.3 states “Mechanical anchorages, if used, must be made from the materials provided, as specified in paragraph 2.5.7 and ARE included in the total cost.”

Q: Can an openwork beam profile be used?

A: Section 2 of the Official Rules describes the structure geometry requirements. The open work (castellated style picture shown) may NOT be constructed as it is non-prismatic. Specimens must have a constant, uniform cross-section throughout the length.

Q: How many composite rods will be in the set we will receive?

A: The number of FPR bars in the kits varies per year. In 2026, a total of 12 bars (2 each from 6 different manufacturers) are provided.

Q: Can only bachelor’s degree students participate in the FRP composites competition, or can second-cycle master’s degree students also participate?

A: Per Section 1.2 of the Official Rules “Each team must consist of at least two and not more than eight students currently enrolled in an undergraduate program...”

Q: I am confused about the amount I have to put on the cost form in the “Measured Batch Weight” column—if, in that column, I have to put the quantity of all my mixtures including beam and cylinders? In the event that the mixture is reused for the Abrams Cone test, would that amount no longer be included in the cost form?

A: Measured Batch Weight is the weight of all materials used to produce the batch of concrete from which your competition structure and all four companion cylinders (three for 7-day tests and one to bring to the competition) are produced. This also includes any additional concrete for the slump tests and any “extra” concrete left over after pouring. The mixture and cost form should include the quantity of materials used to make ALL of the concrete. The team MAY reuse the concrete from the slump test in their specimen and/or cylinders to reduce the batch size. Please note, this is also discussed in the FRP webinar. You are encouraged to review.

Q: We would like to know how many slides we can upload in the presentation? Additionally, we would also like to know if you can post images that justify it. Would there be any penalty for the bending made in the rod? The number of rods used is three and not two.

A: Please refer to the Presentation Template on the FRP Composites Competition page. There is no limit on the number of slides. You may add or remove slides as needed. You are welcome to include images on the slides. Students are encouraged to research bar manufacturing and fabrication processes prior to attempting to bend bars. There is no penalty for bending the FRP bars.

Q: We are seeking clarity on how to differentiate between the calculated and predicted ultimate loads and explain this difference effectively in our presentation. We are particularly interested in understanding the nuances between these terms when we have already calculated the failure load using shear capacity and bending resistance, adhering to standard codes.

A: The calculated ultimate load corresponds to the load calculated using ACI or other code provisions. However, these code provisions may include factored loads, strength reduction factors, assumptions about material behavior, and may not consider concerns related to specimen construction, bar spacing, cover, or other reinforcement patterns. They are also based on known failure modes such as shear and flexure. Therefore, we permit the team to select a predicted ultimate load as that equivalent to the calculated ultimate load using code provisions; or, the team may choose to increase or decrease the calculated load to some value that the team believes will better predict the load at failure due to other considerations.

Q: Do we need to submit the required files both by email and via the portal, or is uploading them via the ACI website portal enough?

A: All files must be submitted via the online portal. Files will not be accepted via email.

Q: We are wondering if we could substitute a percentage of our coarse aggregate with high-density recycled plastic. Would this also result in any sustainability credits?

A: 4.4. Sustainability credits will be granted for reduction in cement content and for use of recycled supplementary cementitious materials (SCMs). NOTE: there are no sustainability credits provided for recycled aggregates at this time. The subcommittee will consider modifications to the rules for future competitions.

Q: It seems acceptable to use fiber-reinforced polymer (FRP) bars that are cut and shaped to mimic stirrups. These FRP stirrups can then be attached to the longitudinal reinforcement using non-metallic wire. Is it also permissible to bend the FRP bars to create stirrup shapes and anchor them around the longitudinal reinforcing bars?

A: Students are permitted to fabricate the provided FRP bars as appropriate for their designs, including cutting and bending the bars (if desired/feasible). Students are reminded of Section 2.5.4. Chemical admixtures meeting ASTM C260, C494, or C1017 are allowed. Epoxies and other polymers, glue, and binders may NOT be used.

Q: Are we allow to use the FRP bars as the shear reinforcement? Like stirrup, ties, etc.

A: Yes, you may use the provided reinforcement in any manner you deem appropriate.

Q: Is there something holding the beam on the left-end and right-end side during testing?

A: Vertical supports are located at the beam ends as shown in the figure of Section 2. Lateral bracing is not provided at the supports or along the length of the specimen. A picture of the test set-up is shown in Figure 3 showing the lack of lateral bracing throughout the specimen.

Q: If we use FRP stirrups in an 850 mm clear span, do they meet the requirement of 2.6.3 regarding reinforcing support?

A: Please note: FRP stirrups were not provided in the FRP kit from ACI. Students may only use provided reinforcement. If teams choose to utilize the provided reinforcement cut to replicate a stirrup, these cut bars may be attached to the longitudinal reinforcement for specimen fabrication purposes. Attachment of the shear reinforcement to the longitudinal reinforcement must be made using nonmetallic materials or galvanized or made from galvanized (zinc-coated) or coated.

Q1: Fy (tensile strength) of the FRP bars sent?

A1: The guaranteed ultimate tensile strength from the bar lot is not provided. Students shall use the manufacturers values as any design engineer would do in practice.

Q2: Price of the bars per weight?

A2: This price is not required, as the students must pay for one complete bar if they use any part of the bar. Students may not price bars in proportion to the length used or by weight.

Q3: Regarding the stirrups should shear reinforcement is to be provided, do we have to use the FRP bars sent as well?

A3: Yes, only provided reinforcement may be used.

Q: Is there a rule or restriction about minimum or maximum aggregate dimensions?

A: There is only one requirement for the aggregate: 2.5.3. Any type of nonmetallic aggregate may be used. Please note the "any type" text. Therefore, there are no minimum or maximum size restrictions on the aggregate.

Q: Can we use epoxy to connect reinforcement?

A: Please refer to Section 2.5.4. Chemical admixtures meeting ASTM C260, C494, or C1017 are allowed. Epoxies and other polymers, glue, and binders may NOT be used.

Q: What would happen if my beam resists more than 67 kN? For example, if my beam were to resist 75 kN, would my equipment have a penalty or would my ultimate load become 67 kN?

A: See Section 3.3. The maximum load achieved will be recorded as the maximum load prior to failure of 67 kN (15,000 lbs), whichever is smaller. There is no penalty; beyond the 67 kN load limit for Pult.

Q: Can we use Portland cement type III, high early strength cement.

A: See Section 2.5.2. The cementitious materials shall consist of any combination of Portland cement meeting the requirements of ASTM C150, or blended cement meeting the requirements of ASTM C595 or ASTM C1157. ASTM C150 states that “This specification covers eight types of Portland cement: type I, type IA, type II, type IIA, type III, type IIIA, type IV, and type V.

Q: Can we use micro silica instead of Silica fume?

A: Silica fumes and microsilica are the same and are covered in “Section 2.5.2 The cementitious materials…”

Q: I have one question on the beam geometry. I see in the rules that we can have a T element. My question is the flange could be either at top or at bottom?

A: The flange may be located anywhere on the beam.

Q: For attending in the FRP competition, other than the registration that we need to do throughout the competition website, do we need also to register in the ACI convention which will be held on late October as this competition is part of that convention?

A: Yes, to attend the competition, you must also register for the convention. Please register here or with ACI's Customer Service Department at (248) 848-3800 Monday - Friday 8:00-5:00 P.M. ET.

Q: For the geometric design of the beam according to the rules that have been sent to us, it has a maximum of both height and width in the cross section but not minimum measurements. Therefore, our question is: Is there a minimum for those transverse dimensions in the beam? Since the longitudinal section, according to the rules, has a maximum of 1000 millimeters and a minimum of 950 millimeters.

A: There are no minimum dimension requirements for width and height. However, the students should consider that the loading plates (centered on the member and spaced 250 mm apart) and end reaction plates measure 50 mm by 50 mm.

Q: Is the use of polystyrene perlite as a lightening aggregate is allowed?

A: Please reference to "Section 2.5.3. Any type of nonmetallic aggregate may be used." Perlite is made from expanded volcanic glass and is nonmetallic. In addition, polystyrene is defined as a stiff, synthetic resin produced by the polymerization of styrene, which is also nonmetallic. Neither of these materials constitute fibers and both are nonmetallic, so both materials are permitted as aggregates.

Q: What is the measured batch quantity?

A: The measured batch quantity is the total amount of concrete that the team mixes; this includes their beam, all cylinders, and any additional material needed for a slump test or excess.

Q: Must the cross section dimensions (width) match the diagram exactly? For example, if our width is 6 cm and there are some areas that measure 6.8 cm measurements, is that OK? Is there a tolerance for those measurements?

A: Yes, the actual dimensions should be the true dimension of their beam. If the beam did not come out to the size intended, they should revise the dimensions on the diagram. We use these dimensions to verify the beam weight is consistent with the provided mixture design.

Q: Is this consideration applicable to the Chemical Admixture Dosage? = mL/100 kg of cementitious material (example: cement + fly ash) or only for cement?

A: You may enter the Dosage in the left column either way, but the actual dosage in mL in the right column must be correct, as this is what is used to establish the cost. Our preference would be that you calculate the dosage in the left column based on all cementitious material.

Q: Does our beam need to conform to ACI 440 in any way?

A: The beam MUST conform to FRP Composites Competition Rules. It may or may not conform to ACI 440.

Q: Can FRP bars be used as aggregate?

A: Section 2.5, Structure Materials of the Competition Rules, states that only materials listed in the Official Mix and Cost worksheet may be used. This would include the reinforcement. The bars may be cut up and added to the beam, but they would be considered "reinforcement" and not part of the concrete mixture design as aggregate. They should, therefore, be shown scattered in the sketches of the Official Mix and Cost worksheet.

Q: Is the T-beam a rectangular shape?

A: The T-beam shape is not a rectangular shape itself. It is comprised of rectangles, but not a single rectangle. Therefore, the team would enter "no" in the Official Mix and Cost worksheet where it asks, "Is this shape rectangular?"

Q: How can we attach/support shear reinforcement within the clear span? May we use ties or other methods?

A: Section 2.6.3 of the Competition Rules states that "Reinforcing supports are not permitted in the 850 mm clear span. Any manner of bar support including chairs, wires, and precast concrete blocks may be used outside the clear span, as long as the bar support does not act to enhance the behavior of the structure." This section does not refer to ties used to connect bars to each other or to connect bars to the reinforcing supports (chairs, etc.). Ties may be used within the 850 mm clear span. Ties must be nonmetallic or must be galvanized.

Q: Can we use an I-section shape?

A: Yes, an I-section shape is permitted. Note that it would be classified as a non-rectangular shape. Therefore, the team would enter "no" in the Official Mix and Cost worksheet where it asks, "Is this shape rectangular?"

Q: What is the design compression strength for GFRP?

A: This information is not provided as part of the competition. Student teams are encouraged to do research on this by seeking out information in ACI literature and scholarly journals.

Q: Does a "prismatic section" mean that the FRP must also be constant along the section?

A: No. For this competition, a section is defined as prismatic (or non-prismatic) based only on its overall concrete section shape. Changes in reinforcement location or quantity along the length of the beam are not considered in establishing whether a shape is prismatic or not prismatic.

Q: How long must an FRP bar be inside the concrete beam? What is the minimum length for FRP bars inside the beam?

A: There are no limitations on the length of the FRP bar used in the beam, except that "The structure's overall length may not be less than 950 mm (37.4 in.) nor more than 1000 mm (39.4 in.), including any protruding reinforcement."(Section 2.2 of the Competition Rules.)

Q: Are we allowed to cast trial beams; and, if so, does that material count toward our batch size?

A: Yes, the team may cast trial beams. Section 2.5.5 of the Competition Rules states that "Teams must provide the measured weights of all materials used in the concrete batch prepared to cast their competition structure…" Therefore, the weight of materials used to cast trial beams or to experiment with mix designs should not be included in your Official Mix and Cost worksheet.

Q: Can I put foam inside concrete beam mix? Can we use foaming concrete as a lightweight concrete?

A: Only materials listed on the Official Mix and Cost worksheet are allowed. Neither foam (such as Styrofoam), nor reactive foaming agents that produce cellular concrete, may be used.

Q: Section 2.5.3 of the rules say that any type of nonmetallic aggregate may be used. Is silica sand permitted? What would be the unit price on the cost form of the material?

A: Silica sand, which is an ultra-fine aggregate used in ultra high performance concrete (UHPC), is permitted and should be considered as “Fine Aggregate” on the Mix & Cost Form. Be sure to note that silica sand is different that silica fume, and silica fume would not be considered as aggregate.

Q: The rules say that no supports like wire or chair are allowed in the middle clear span of 850 mm. But right now we are thinking about casting the beam with the FRP reinforcement hung from top with tape (electric tape or clear tape) or threads. Are the tapes or threads allowed to stay in the middle 850mm clear span, since they are not solid supports and will not have any structural contribution?

A: No. Per Section 3.6.3 of the rules, all reinforcing supports – regardless of the type of support used – must be located outside of the middle clear span of 850 mm.

Q: Do glass fibers, metallic fibers, or polypropylene fibers qualify as aggregate?

A: No. Fibers of any type do not qualify as aggregate. Fiber-reinforced concrete (a concrete mixture with short fibers, no matter what the type) is not permitted.

Q: On the ACI website, past winners and scoresheets are available. Would it be possible to view their submitted design .pdfs as well?

A: PDFs from previous competitions are not shared. However, the past scoresheets provide insight into how scoring is done.

Q: Are integral pigments and color-coating treatments not allowed in the competition? Are there any methods of personalizing the structure outside of the identification number or is this a deliberate competition design consideration?

A: Refer to Section 2.3. Structure Markings. Personalization may be accomplished with felt-tip markers.

Q: Does the structure weight in section 2.4 of the rules refer to the beam weight including the FRP reinforcement?

A: The total structure weight is the beam weight and DOES include the weight of any FRP reinforcement that is used.

Q: Is there a cost for the kit to be shipped?

A: No cost is required of the teams. Only 1 kit is provided per team.

Q: How quickly can we receive our kit?

A: Kits will be shipped once both required documents are uploaded to your registration file (the FRP Kit Order Form and the Verification Letter.)

Q: After casting our structure, we realized that it was a little bit longer than permitted by the rules and a little bit heavier. Are we allowed to saw cut our specimen to make it conform to the rules?

A: Yes, the specimen may be saw-cut after casting if necessary to achieve dimensions and weight that conform to the rules.

Q: How do we distinguish between the different reinforcement manufacturers' bars, and what are the material properties of each?

A: Please see the "Reinforcement Identification Guide and Product Datasheets" link posted on the competition website.

Q: If I do not have enough materials from the original kit, will I have the opportunity to get more materials to complete the final specimen for competition?

A: No. Each student team will only be sent one complete set of materials.

Q: I see that an electronic copy of the Official Mix and Cost Form is due by the pre-competition deadline date and that a hard copy is due at check-in. Do the two have to exactly match in terms of predicted loads?

A: The predictions must match exactly. Student teams are not permitted to adjust their predictions after the pre-competition deadline date. Should they do so, the prediction values initially submitted will be used for determining the prediction discrepancy.

Q: The three cylinders and the slump test that are listed on the Official Mix and Cost Form aren't mentioned in the official rules or any other page of the submittals. Is it a requirement to perform these tests?

A: All requested information on the Official Mix and Cost Form must be provided, so you will need to perform a slump test and break three cylinders for 7-day strength. A fourth cylinder must also be produced and brought to the competition along with the structure.

Q: Can we use capping for the concrete cylinders?

A: You may cap the cylinders you test for 7-day strength, but the cylinder that is brought to the competition should not be capped.

Q: Can we reuse the concrete for the slump test in one of our cylinders? This would save on cost.

A: Yes, reusing the slump test concrete in the cylinders or structure is permitted, should teams choose to do so.

Q: On the diagram, it says that the end reactions are applied through flat plates that are at least 2 x 2 in. (50 x 50 mm). The design that we are working with won't work with plates that size. The wording makes it seem like bigger plates are a possibility.

A: The beams must be able to be tested with plates any size from 2 x 2 in. (50 x 50 mm) on up. Designs that do not meet this requirement may not be able to be tested at the competition. It is the team's responsibility to ensure that their beam can be safely tested with end reactions applied through flat plates that may be as small as 2 x 2 in. (50 x 50 mm).

Q: Of what material will the reaction points be composed of when the structure is tested?

A: Steel.

Q: May we use a mixture of reinforcing bars?

A: Different types of FRP bars may be used in the same structure, as long as the only reinforcing materials used are from the FRP reinforcing materials kits and all materials used are reported on the Official Mix and Cost form.

Q: Is the FRP allowed to show?

A: FRP may be exposed in the structure.

Q: What cannot be done to the reinforcement bars, or what are the limitations on the manipulation of the bars?

A: The only limitation on manipulation of the bars per the rules is that you are not permitted to prestress the reinforcement.

Q: Can the FRP surface be roughened to increase or decrease the bond strength?

A: Yes, the rules permit this. However, the surface of the bars may not be coated with any material. The bar surface (original or modified by roughening) must be in direct concrete with the concrete within which it is embedded.

Q: Are you able to bend the FRP bars in any way to create a hook at the end of the bar? Can the bars be melted?

A: You should research the materials prior to doing anything to the bars other than cutting them, as it is possible that activities such as heating may destroy material properties. Also keep in mind the stress-strain characteristics of these materials that are linear elastic to failure—or in other words, the bars will not yield.

Q: What constitutes "mechanical anchorage" of FRP bars?

A: "Mechanical anchorage" is the use of any type of mechanical device (such as end plate) to anchor the bar, other than relying on the bond between the concrete and reinforcement.

Q: Are we permitted to use metal wires or similar items such as paper clips to locate the FRP inside the beam?

A: Yes, but only if the metal is galvanized (zinc-coated) or coated with nonmetallic materials. Otherwise, bar supports must be nonmetallic. Regardless, any bar supports must be located outside the clear span and must not act to enhance the behavior of the structure, such as by anchoring the bar in the concrete.

Q: Do glass fibers qualify as aggregate?

A: No, glass fibers do not qualify as aggregate. Fiber-reinforced concrete (a concrete mixture with short fibers, no matter what the type) is not permitted.

Q: Is Micron 3 allowed?

A: Only materials listed on the Official Mix and Cost worksheet are allowed. Although Micron 3 may meet requirements of ASTM C618, it is not fly ash meeting ASTM C618 so it would not be allowed.

Q: Is the use of lightweight core permitted for the structure?

A: It depends on what you consider a "lightweight core" to be. If you mean a core of lightweight concrete, then yes, that is permitted. But if the lightweight core is made of any material other than concrete, it would not be permitted.

Q: As far as type of cross section, we read the rules for competition several times and we did not find anything saying that we are not allowed to do a hollow section, so just to make sure, are we allowed to have a hollow section for our beam? And if yes, are we able to use something like a pipe to create the hollow or is there any restriction on what we use to make the hollow happen in our beam?

A: A hollow section is permitted by the rules; however, nothing used to create the void may permanently be left attached to the member. The final structure must be comprised of concrete and FRP reinforcement.

Q: Questions regarding the beam rehearsal: Will they use any standard in the testing machine? Will the test be standardized by any test standard?

A: The test procedure is defined in Section 3. The Testing Process of the FRP Composite Competition Rules. General information taken from this section states that the load will be applied by a pivoting load plate at an approximate rate of 2.5 mm/min. A seating load of approximately 56 lbs will be applied and the seating load and piston movement will be recorded. Additional load will be applied until the structure fails or is loaded to the test fixture's capacity of 67 kN (15,000 lbs).

Q: Can we have 2 mix designs for different areas of our beam

A: Yes, you may have two different mix designs. However, the team must designate which mix design is being used in what areas of their structure on their structure drawings. The team should submit two different official mix and cost forms with appropriate volumes for each mix design shown. Types and quantities of FRP bars should be shown on only one Official Mix and Cost From.

Q: The chapter would like to inquire regarding transportation methods for the beam for travelers. We would like to know what previous teams have done for transportation as we do not want to have the beam be checked-in luggage for the sole purpose of it being disturbed, drilled into, or destroyed.

A: Depending on the size of the project, teams typically bring it as a carry-on. When possible, they use a suitcase or longer luggage piece such as what you might use for a musical instrument or athletic equipment. We have seen a lot of creative ways to transport — modified guitar cases, pelican boxes, and custom-built cardboard creations all come to mind. We agree that it is best not to check it if it can be avoided. There are usually 1 or 2 every year that end up broken in checked bags.

You should have a list of the materials used in the construction process, your registration receipt for the convention, and a copy of the competition description available for customs to read so that you can explain why you are carrying concrete into the USA.

Most importantly, call ahead to the airline and explain what you are bringing (length/width/weight) because they may require you to check it below the plane anyway. In that case, you will need to do everything you can to prevent it from breaking if it is being stored below.

Insulate the beam with foam, blankets, or some other material so that it doesn’t crack, and it will need to be accessible to customs in the event that they want to inspect it.